DRAWBOT

AND OTHER ADVENTURES IN PHSYICAL COMPUTING

PROJECT

DrawBot

ASSIGNMENT

Prototyping Studio—Physical Computing + Visualization

TOOLS

Arduino

Lilypad

Processing

MakerBot 3D Printer

I had been looking forward to electronics prototyping since, more or less, the beginning of time, so when we were given a decent amount of freedom for the assignment, I decided to attempt multiple projects.

IDEATION

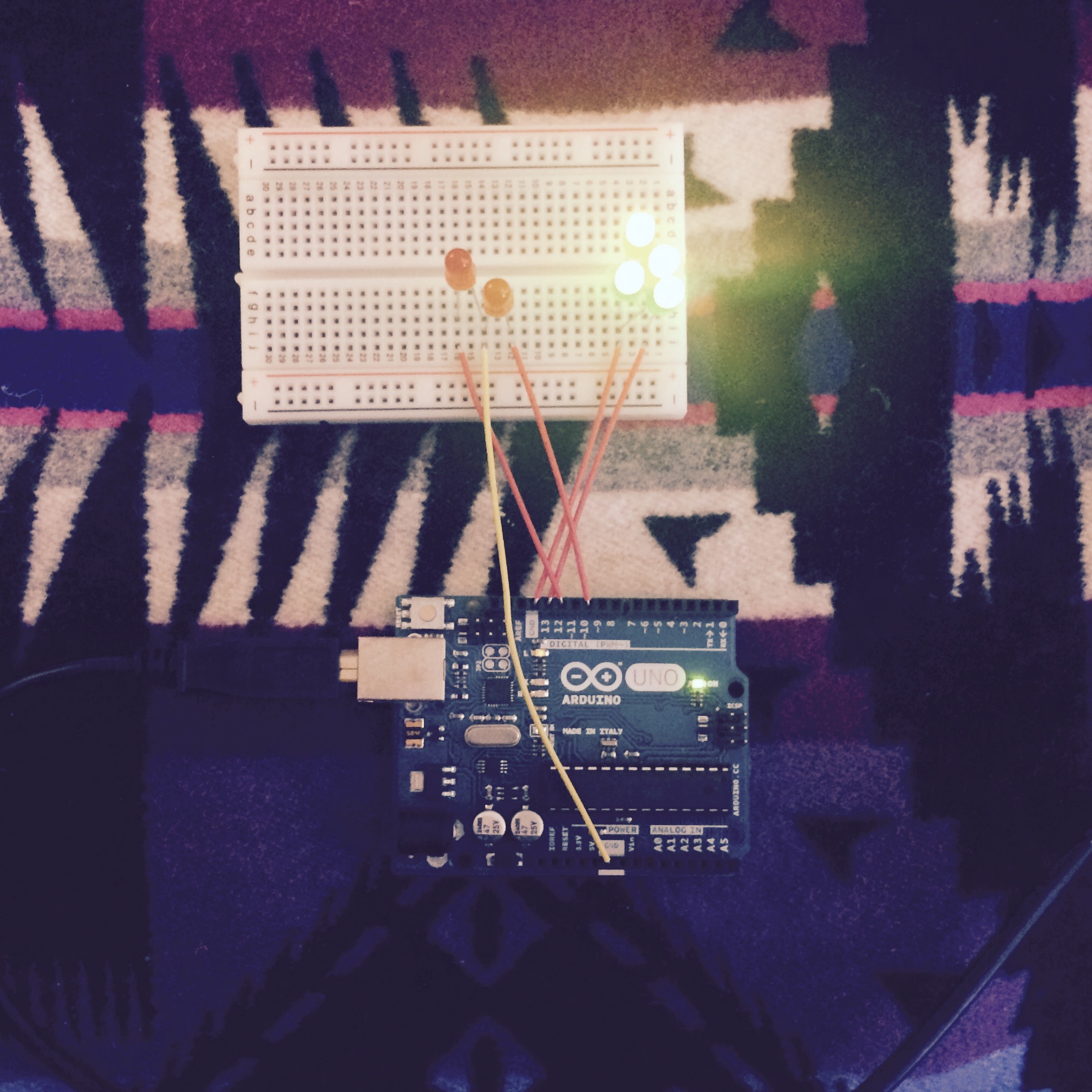

I spent some time over the weekend playing around and getting comfortable with my new Arduino; once I felt I had learned enough to begin ideating about project ideas, the brainstorming process began.

My mind was overflowing with ideas for this assignment: build an interesting temperature visualization using Processing or large, RGB LED lights that could be displayed on a wall, create a sort of mood-ring-type device by wearing the temperature sensor on my skin and incorporating a real-time visualization of the data, or a drawBot that could make cool designs all on its own.

I decided to attempt all of my ideas, with the intent of later finishing the projects I couldn’t complete in time for the assignment due date. After some time spent Google-ing, I found an online tutorial that included parts required for building the bot, so long as I could 3D print them. After asking Andy’s permission to use the printer in the design lab, I was set! After working through some issues with SD card configuration and a few other unknowns, I had the necessary pieces after waiting just three short hours for them to print.

EXPERIMENTING WITH THE LILYPAD

I had ordered the necessary micro-servos and RGB LEDs, and was now waiting for them to arrive in order to move forward with my projects. In order to use my wait time most efficiently, I decided to begin experimenting with the Lilypad, and practice sewing with conductive thread. This was far more challenging than I had expected! It took several hours of reading, learning, trying, failing, and trying again before I had successfully connected + to + and - to -, with no overlap, and had a blinking Lilypad without any computer connection. Although not a tremendous achievementnor a compelling project on its own, the practice was a tremendous learning experience and has given me the base skills to create more complex projects. Should time allow, I intend to sew red LEDs to the heart design on the tote, and program the Lilypad so that they light up in some sort of interesting pattern or design.

PUTTING THE PIECES TOGETHER

When the micro servers finally arrived, I began working on the drawBot setup. Like most things, this was far more complicated and time consuming than I had expected; simply installing the screws was nearly impossible as the printed plastic pieces had openings too small for the screws to fit. Eventually, however, I had a completed build to work with.

Once I had assembled the bot and tried it out, I realized the servos did not have enough power to work the device with the current plastic situation. Recognizing I needed help to make it work, I sought out the assistance of Tayseer, an electrical engineer in my program. Tayseer was gracious enough to spend a few hours making small changes and adjustments to my set-up. While he tinkered with the drawBot, he talked me through the steps he was taking; I learned a lot from Tayseer’s help.

PROBLEM SOLVING

Later, to try and improve the device which was hindered by imperfect plastic due to 3D printing, I attempted to sand paper a couple of the pieces to create a smoother experience. Additionally, because the screw on the bottom of one of the rotators also impeded the bot, I applied a layer of puffy paint type glitter glue to the bottom of the main piece to raise the device and allow for smooth movement.

After a few adjustments and quick fixes, I was able to get the X-axis working, drawing a straight, horizontal line back and forth across a piece of paper. Although I ran out of time to work on the Y and Z axes, this assignment was still, above all else, a tremendous learning experience. Less concerned about completing a polished product, and incredibly eager to get my hands dirty experimenting and trying anything and everything I could possibly get my hands on, I’d call this week a success.